What are Confined Spaces?

When you find yourself working in a confined space, do you know what you can do to reduce your risks?

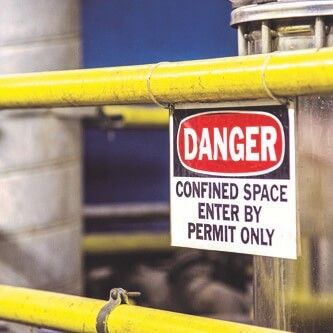

According to OSHA, the Occupational Safety & Health Administration, confined spaces are areas that are not necessarily designed for people, but they’re large enough for workers to enter and perform work

Confined space has limited or restricted openings for entry/exit, unfavorable natural ventilation and is not intended for continuous occupancy. These spaces include, but are not limited to, tanks, silos, storage bins, hoppers, pits, tunnels, equipment housings and ductwork.

You may find yourself in a confined space at work or at home – and the first step in preventing any issues when working in this type of area is recognizing that it is indeed a confined space. Then, follow these tips from Advanced Consulting & Training to reduce your risk:

- Before entering the space, be sure you can eliminate or control hazardous elements in the environment.

- Pay attention to the atmosphere using an instrument that can monitor the space for hazardous gases that can’t be detected by the nose.

- Make sure the area is well-ventilated.

- Use personal protective equipment.

- Reduce the likelihood of additional hazards by isolating the confined space.

- Be sure there is an outside attendant who is there, ready and able to monitor safety conditions and able to assist in the event of an emergency.

- Always be prepared for a rescue, in case an emergency situation arises.

- Ensure that the lighting in the confined space is good.

- Keep in contact with the outside attendant so you can immediately notify them of problems.

Olympic Steel has an established Confined Space Program that outlines written practices and procedures for the safe entry into a confined space. The program applies to maintenance employees and any individuals or outside contractors who may enter a confined space. The program document can be found on OSSIE.

Questions?

For questions, additional information or support with local safety programs, please contact your local Safety Contact or Tony Dominic, Director – Safety, Health & Environment, at Tony.Dominic@olysteel.com.

Safety First. Always. And, it starts with me.

Olympic Steel | Action Stainless & Alloys | Berlin Metals | Central Tube & Bar | Chicago Tube & Iron | EZ-Dumper | Integrity Stainless | McCullough Industries | Metal-Fab | Shaw Stainless & Alloy

All Rights Reserved | IamOlympicSteel.com | Privacy Policy