Being Berlin Metals

Berlin Metals, based in Hammond, Indiana, offers precision high-speed slitters for very light gauge materials including tin plate and stainless steel.

In April of 2018, Berlin Metals joined the specialty metals segment of Olympic Steel, providing growth in new products and markets.

HISTORY

Berlin Metals was founded in 1967 when the Berlin family purchased Hokin Steel & Tinplate, a company that began in Chicago in 1932. More than four decades ago, Berlin Metals settled in Hammond, Indiana, less than 30 minutes from Chicago. Roy Berlin served as President until he retired in 2019. Dan Harnois joined Berlin Metals as General Manager the same year.

The ISO 9001 Certified facility includes 4 coil slitting lines in a 160,000 square foot production space. Berlin Metals has a workforce of 58 team members that runs two shifts per day. The average seniority for the shop employees is about 16 years, with the 12 longest tenured employees averaging approximately 30 years’ experience. Bob Thompson, Operations Manager, is the most senior employee with 39 years with Berlin Metals, beginning as an hourly employee on the floor.

PRODUCTS

Berlin Metals is one of the largest North American service centers processing and distributing tin mill products and stainless steel strip in slit coil form. With the unique capability to slit very light gauge metals, the vast majority of the material that is run is between .009 and .010 inches in thickness. Slitters run at a high speed of up to 1,200 feet per minute to accommodate low gauge materials and hold tight tolerances of +/- .005 inches with precision-slit widths as narrow as .375 inches from master coils. With these niche capabilities, Berlin Metals also slits product for other divisions within Olympic Steel.

In the last three to four years, the mix of metals that Berlin Metals produces has shifted from primarily tinplate to a 50/50 mix of stainless steel and carbon tin mill products. Tinplate is actually carbon steel that has been coated with a tin substance at the mill while in coil form. The tin coating makes the metal resistant to corrosion and is nontoxic so it can be used in food-related applications, such as soup cans.

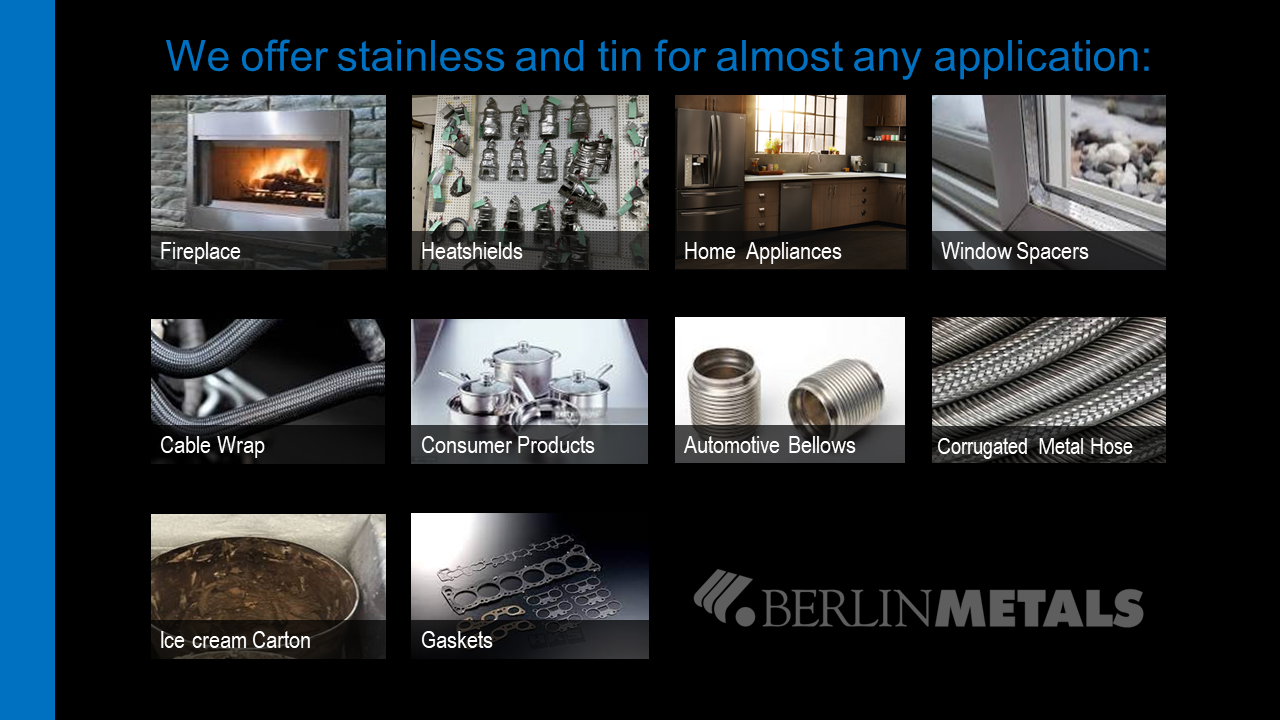

The industries served by Berlin Metals consist primarily of automotive, communications, housing and commercial manufacturing. Berlin Metals provides tinplate or stainless steel in things you may run across in your daily life. You’ll find it in aerosol spray cans, the spacer in between the panes in your windows, your fireplace chimney liner, underground telecommunications cables for internet, gaskets in the engine block of your car or tractor, and the very best place to run across tinplate: the top and bottom ridge on the 3-gallon tubs of ice cream where you order your favorite scoops!

To learn more about the products and services of Berlin Metals, visit berlinmetals.com.