Fabrication: 101

Fabrication is how we make things out of metal. It is a key part of Olympic Steel’s future.

From automotive to construction machinery, restaurant equipment, and so much more, we make the pieces and parts out of metal that make these end-use products possible. Our customers in various markets, often referred to as OEMs (Original Equipment Manufacturers) engineer the product designs and market them to customers. We help with that important middle part of the process – making the components that our customers assemble into the final products we see and use every day.,

HISTORY

Fabrication isn’t brand new at Olympic Steel. In 1999, the Company opened its first fabrication-focused processing facility in Chambersburg, Pennsylvania. Since then, we have expanded organically (installing equipment in existing divisions to support the needs of current customers) and through acquisitions, with new brands like McCullough Industries (producers of WRIGHT Self-Dumping Hoppers), Shaw Stainless & Alloys (producers of barrier defense bollards and custom water treatment tanks), and Metal-Fab (producers of commercial and residential air filtration products). We’ve also opened fabrication-focused locations, like our Buford, Georgia and Bartlett, Illinois facilities.

From our beginnings as a steel processor, our fabrication capabilities have evolved to provide various levels of processing that include fully welded structures for diverse industries out of multiple metallic materials. Today, we operate more than 350 pieces of manufacturing equipment, with some type of fabrication services offered in the majority of our locations.

PRODUCTS

To support our customers, we cut shapes out of metal sheet and plate, using laser, plasma and oxyfuel cutting tables. Depending upon the customer’s needs, we manufacture parts on our machining centers, bend and form them on brake presses, manually or robotically weld various component parts together and/or assemble collections of parts to make it easy for the customer to complete the final assembly and prepare the products for sale to an end-use customer.

It's a multi-step process, and it’s an essential piece of Olympic Steel’s growth strategy. By offering fabrication services, we are able to better support our customers by allowing them to focus on what they do best – designing and marketing their products. Fabrication, sometimes referred to as value-added processing or simply manufacturing, allows us to improve our margins and manage the volatility that is often associated with traditional metal distribution. The more complex an operation – the more steps it includes – the harder it is to move to another processor, resulting in long-term, more closely integrated business relationships. (This is also why quality, one of our Core Values, is so critical!)

Fortunately, we already have some fantastic customer relationships to build upon - producing parts and equipment for consumer use, such as grills, tractors, refrigerators, cars and trucks, and items you’d find in kitchens, offices, and restaurants – to name just a few!

OUTLOOK

The fabrication business outlook is strong! OEMs have shifted their focus to product development, assembly and distribution. This has opened up opportunities to invest in new technology to provide more value-added processes and fabrication at the service center level – where we operate in the manufacturing supply chain. Olympic Steel has strong relationships with some of the largest OEMs, we are a recognized leader in the service center industry, and as we continue to invest in our people, our facilities, and our capabilities. The fabrication business is well-positioned to support our enterprise-wide goals of doubling Olympic Steel’s profitability over the next five years.

TEAM

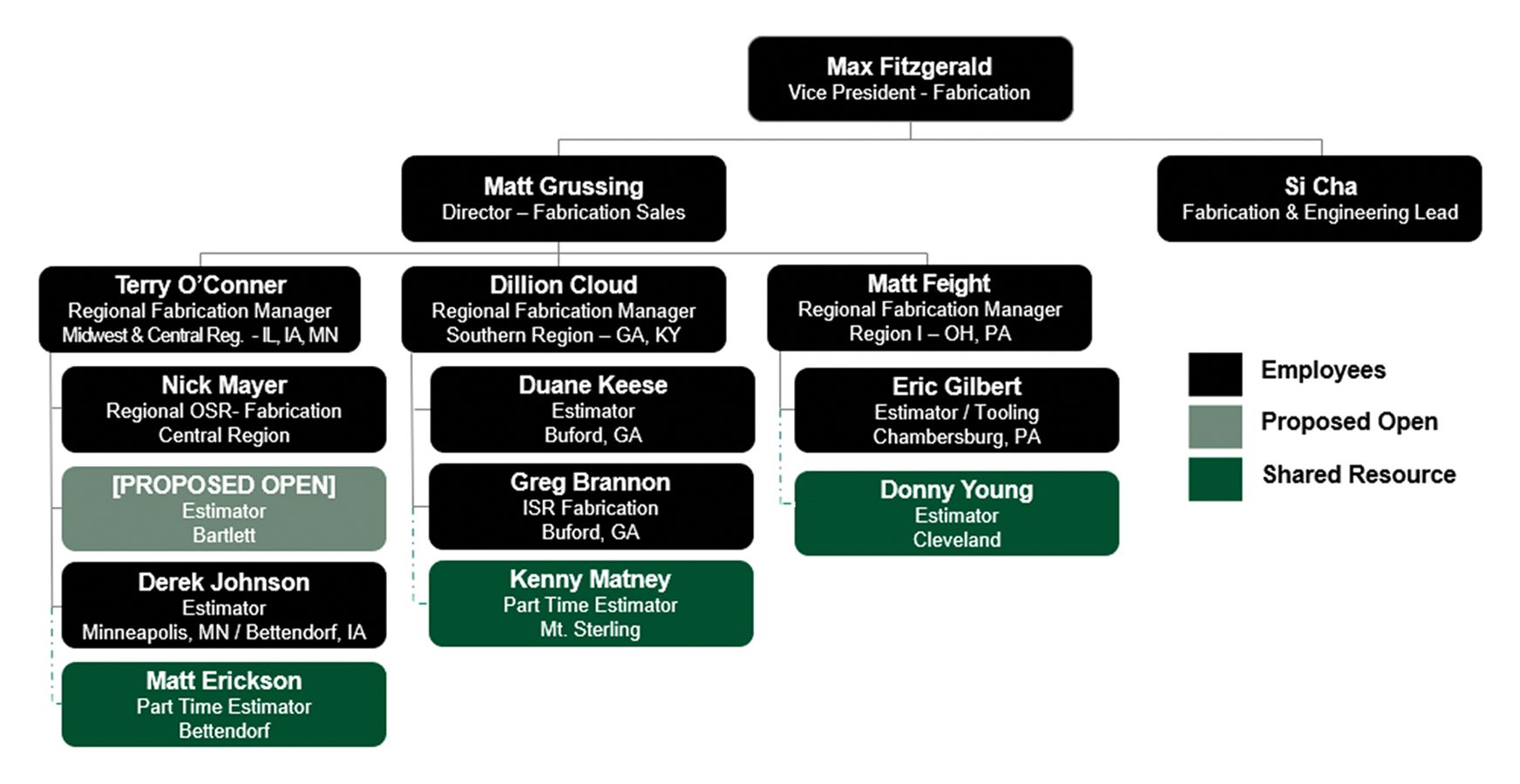

To support this strategic growth opportunity, Max Fitzgerald (Vice President- Fabrication) was brought onboard in mid-2023. Tasked with building a strong team and executing our strategy, Max has assembled Olympic Steel’s first fabrication team with over 150+ years of combined fabrication experience, ranging in roles from general managers to machine operators.

Since 2023, this team has travelled Company wide, learning the current capabilities and exploring the possibilities. In March 2024, the first Fabrication Strategy was presented to leadership and includes four key tenants:

- Organizational Development,

- Operational Alignment,

- Operational Excellence, and

- Sales Strategy and Growth,

All of these align well with the Corporate strategy of doubling Olympic Steel’s profitability in the next five years.

We have the buying power, the strategy, and the people that will allow the company to grow safely and profitably well into the future. With increasing margins and improved quality and delivery, we will be able to invest in the people and technology that will make us the supplier of choice for our customers. The future is bright!

To learn more about our processing services, visit olysteel.com/processing-services.