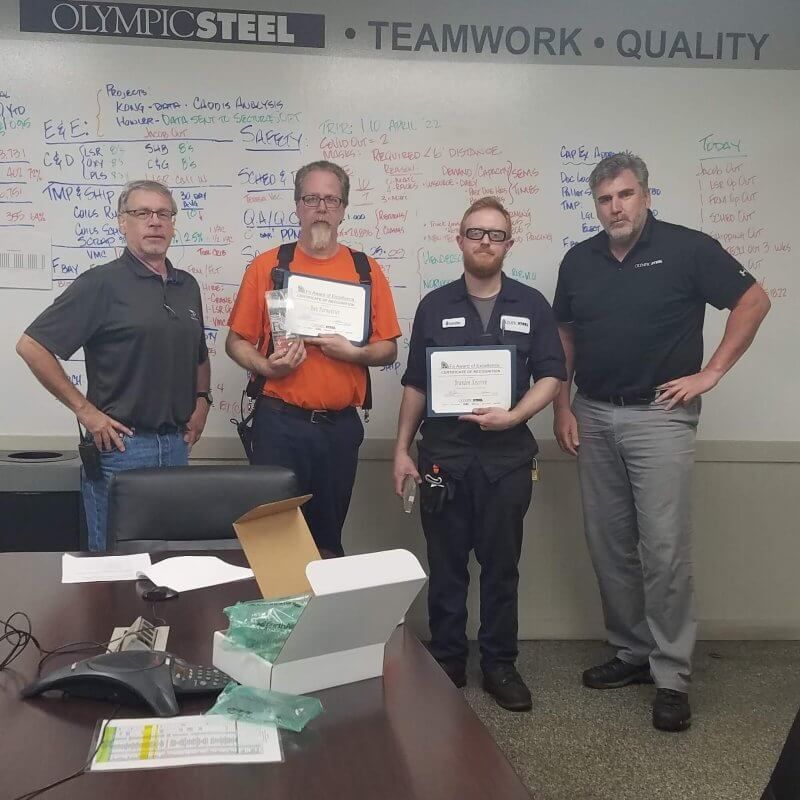

Olympic Steel – Bettendorf, IA: Tim Hughes

The Bettendorf, IA division has a 1000-ton press break with an adjustable opening bed. The division uses shim plates of different thicknesses to allow for various openings. The shims are not easily identified. When the wrong shim is used, it throws off the opening, resulting in scrap, die failure or, possibly, injury. Tim Hughes, Machine …

At the Bettendorf, IA division, when you load a sheet product on a Timken rack (a customer-specific requirement), the rack must be positioned on the packaging line with two 5-foot 4x4s on either end, under the rack.

When the wrong shim is used, it throws off the opening, resulting in scrap, die failure or, possibly, injury. Tim Hughes, Machine Operator, grouped the shims by thickness, then painted them each a different color to easily identify each shim. He also created a color-coded shim chart to show how many of each color to put on each side to allow for the desired bed opening. This simple change is incredibly effective – reducing downtime and increasing productivity. Prior to the color coding, a bed change could take up to an hour; now a bed change takes 30 minutes or less.

Lesson Learned: This is a great example of a poka yoke and perfectly illustrates how a simple solution to an everyday encounter can have a huge impact on productivity.