2024 LSSGB Graduate Projects

The 2024 Lean Six Sigma Green Belt graduating class completed projects that will save almost 1.5 million dollars annually. Learn more about each member of the class and what’s required to become a LSSGB.

Introducing your 2024 Lean Six Sigma Green Belt graduating class (click on each participant’s project to learn more):

- Dana Beard,

Regional QSHE Manager – Action Stainless, Dallas, TX

Project: Logistics Strategy - Matt Erickson,

Plant Engineering Manager – Olympic Steel, Bettendorf, IA

Project: Bettendorf Temper Mill Lumber - Machelle Haessler,

Quality Assurance Manager – Olympic Steel, Bettendorf, IA

Project: IA Temper Mill Scrap Reduction - Abby Box,

Controller – Olympic Steel, Bettendorf, IA

Project: IA Coil Stocking Program - Jeremy Contreras,

Fabrication Team Lead – McCullough Industries, Kenton, OH

Project: Welding Consumables - Lance Harris,

Safety Specialist – McCullough Industries, Kenton, OH

Project: Production Scrap on Bar Saws - Lea Hall,

Service & Scheduling Manager – McCullough Industries, Kenton, OH

Project: WIP Process - Archie Adekoya,

Production Supervisor – Olympic Steel, Minneapolis, MN (Coil)

Project: Skid Inventory - Ryan Koch,

Maintenance Technician – Olympic Steel, Minneapolis, MN (Coil)

MN Coil Maintenance Systems - Katie Vargo,

Production Planning Specialist – Olympic Steel, Minneapolis, MN (Coil)

Project: Packaging Instructions - Tao Lee,

CNC Programmer – Olympic Steel, Minneapolis, MN (Plate)

Project: VMC Run Times - Ivy Katrinak,

OpEx Intern – Olympic Steel, Minneapolis, MN (Plate)

Project: Production Log - James Williams,

Account Manager – Olympic Steel, Minneapolis, MN (Plate)

Project: Fab Part Profitability Reporting

Participating in Olympic Steel's Lean Six Sigma Green Belt Certification program takes dedication and commitment. These participants put in a lot of extra work for the LSSGB projects, in addition to their 'day jobs'.

Certification Requirements

- 112 hours of classroom work

- Completion of DMAIC project over 4 months

- 5 project update presentations

- 80% score on written exam

- Project detail overview report

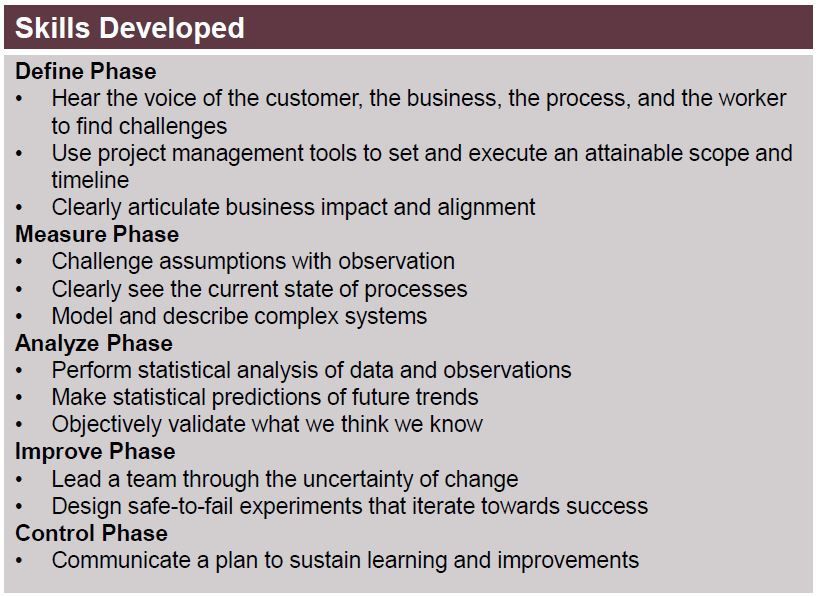

DMAIC refers to the five phases of the program: Define, Measure, Analyze, Improve and Control. Here’s a closer look at what happens during each phase.

Questions? Want to know more?

Learn more about out Central Region Operational Excellence Team (the folks who manage this training program) at IamOlympicSteel.com.

Robert Erion, Safety & OpEx Manager and Lean Six Sigma Master Black Belt

763.847.9858 (internal extension 71444)

Will Robbins, Project Manager and Lean Six Sigma Master Black Belt

763.542.4882 (internal extension 70412)

If you’d like to be considered for Green Belt training, reach out to your General Manager to discuss the process.